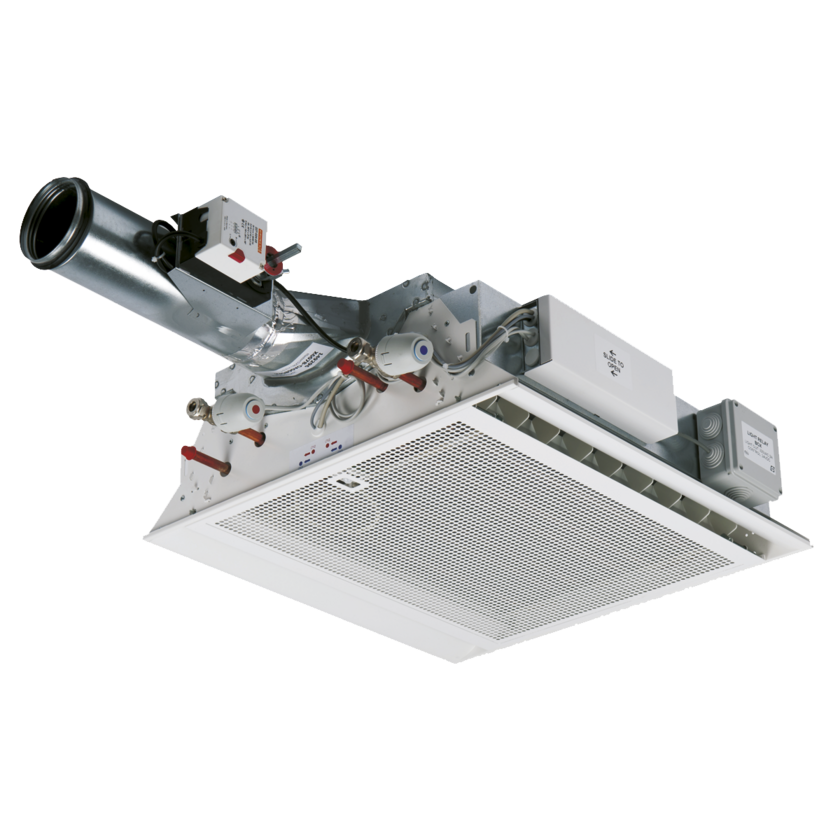

OptimAir Dual Flow

Main features

• Two-flow chambers for supply air volume control (occupied/unoccupied)

• Designed for flush installation in suspended ceilings

• 2-way flexible spread pattern along the suspended ceiling

• Prepared for connection of powering and control

• Adjustable air deflectors for draught-free indoor climate

• Foldable front for inspection and service

• Supply air volumes per unit: up to 125 m3/h (35 l/s) at 100 Pa (when occupied)

Description

• OptimAir-DF (Dual-Flow) is a two-way induction unit for supply air, cooling or optionally, cooling and heating.

• The unit features dual settings and control for supply air flow depending on actual flow requirements, i.e. occupied/unoccupied conditions.

• OptimAir is designed for flush mounting in suspended ceilings and fits standard 600 mm suspended ceiling frameworks, with additional adaptation possibilities to fit most suspended ceiling systems on the market.

• The supply air flow is distributed through supply air nozzles in two directions.

• With the supply air flow as a driving force, room air is induced through the finned coil, which then removes or, where applicable, adds heat.

• The mix of supply air with conditioned return air is discharged via the supply air grille horizontally along the ceiling.

• The nozzles are divided into two groups, one for supply airflow in occupied mode, and a second airflow for unoccupied mode.

• This division allows maintaining the same pressure the lower flow as at the full flow, which provides a higher cooling effect when the premises are unoccupied.

• OptimAir DualFlow is delivered in two variants:

– Variant with fixed nozzles.

– Variant with adjustable nozzles in the supply air chamber of the unit.

• Setting and adjustment of the variant with adjustable nozzles is possible in five positions. Settings are easily done without the need for any other tools than an Allen key.

• The unit is equipped with a motorized on/off damper that switches between the two commissioned air flows.

• The product is equipped with Airflex, adjustable air deflectors. Each deflector can be individually adjusted which makes it possible to achieve a draught-free indoor climate.

• The front grille of the unit is made of perforated sheet metal and is easily folded down for inspection and maintenance.

Material options and finishes

• Powder coated finish.

Sizes (mm)

• Version with fixed nozzles is delivered in 4 length alternatives:

600/1200/1800/2400 with duct dimension Ø100 (build height 157 mm)

• Version with adjustable nozzles is delivered in 3 length alternatives:

1200/1800/2400 with duct dimension Ø125 (build height 185 mm)

Configuration alternatives

• Version for cooling or cooling and heating.

• Selectable water connection side: same as the air duct or opposite side.

• Available in versions with 1 or 2 water circuits.

• Air volumes for occupied and unoccupied mode are based on a specifiied nozzle pressure. The required pressure is specified on order placement according to customer requirements.

• The version with fixed nozzles can be supplied with a certain proportion of the nozzles plugged with the possibility of increasing the airflow at a later time.

Options and accessories

• Integrated control for stand-alone operation or connectivity to parent BMS.

• Complete selection of connection accessories:

– Adjustment damper type ZMC

– Setpoint changer.

– Connection hoses.

– Control valves for water supply.

– Coanda 'cape'.

– Valve actuators.

• Device housing and duct connection made of hot-dip galvanized sheet steel with EPDM rubber gasket.

• Visible parts: casing, frame and perforated front grille made of sheet steel, powder coated in white RAL standard colour. Other colours are available.

• Coil made of copper tubes with aluminum slats.

• Plastic details of Polyethylene.

• For more information about standard materials and colors, see the separate document Product specification which can be downloaded from our website.

• The following information is only a general overview of the of assembly, installation and adjustment procedure. Always refer to the product's operation and maintenence documention (DU-SE/DV-DK) for detailed installation instructions.

• The product is connected to a circular supply air duct. Connection to a straight mounted flexible duct is not recommended.

• Heating and cooling water pipes are installed by a plumbing contractor.

• The length and width of the unit is adapted for flush installation in standard suspended ceilings.

• The product has four vertical slots in the panels for suspension with ceiling hooks in the ceiling structure (see maintenance documentation for details).

• On request when ordering, the product can also be delivered with four factory-mounted suspension brackets for pendants (one in each corner).

• Fittings with pendants are mounted by using a threaded rod and can be adjusted separately in 4 directions.

• Ensure that no damage occurs to the cooling/heating coil when tightening valves and connections. To avoid this, always use a suitable wrench as counterweight.

• When installing the beam, space should be reserved for opening the front grille and accessing the device for cleaning, inspection and service.

• Products with adjustable nozzles can be set based on the positions described in the product's operating and maintenance document (DU/DV).

• Products with fixed nozzles are delivered for a specific air flow at a given nozzle pressure, according to customer requiement (specified at order placement). In this case, the product can be delivered with a certain number of nozzles plugged on delivery in order to increase airflow later if necessary.

• The required flow is obtained by adjusting the current operating pressure with the product in occupancy mode (full flow).

• The air flow q (l/s or m3/h) is measured with the measuring profile in the duct inlet.

• The operating pressure P (Pa) is measured in the hose from the supply air duct.

• In order to be able to adjust the operating pressure, the product should be preceded by an comissioning damper mounted in the duct before the unit, e.g. ZMC or SPD, but not an iris-type damper.

• When installing the commissioning damper, requirements for the preceding straight section should be taken into account, see the specific damper's documentation for detailed information.

• The supply air flow is calculated using the measured pressure over the nozzles or over the measuring rail of the commissioning damper.

• For calculation of K factors, see tables and calculation formula in the operation and maintenance document (DU/DV) of the beam. For K factors with a commissioning damper, please refer to the documentation of the specific damper to be used.

• When the unit is supplied with control options, the product is delivered internally pre-wired from the factory. See separate documentation depending on the current option regarding wiring, commissioning and operation of control and powering components.